Quality

Birinci quality assurance system is designed and implemented with the aim of high customer satisfaction. Being the preferred supplier is the key to Birinci's continuous improvement philosophy. Apart from IATF 16949, ISO 14001 & 45001,ISO 50001 the company has Q1 and JLRQ certificates. The company has also successfully passed the audits of Mercedes Benz, VW, MAN, Scania, Linde and Toyota Material Handling Group.

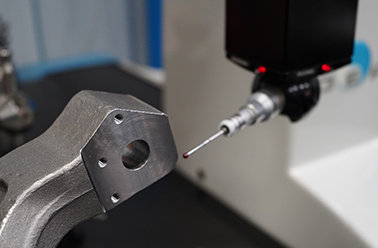

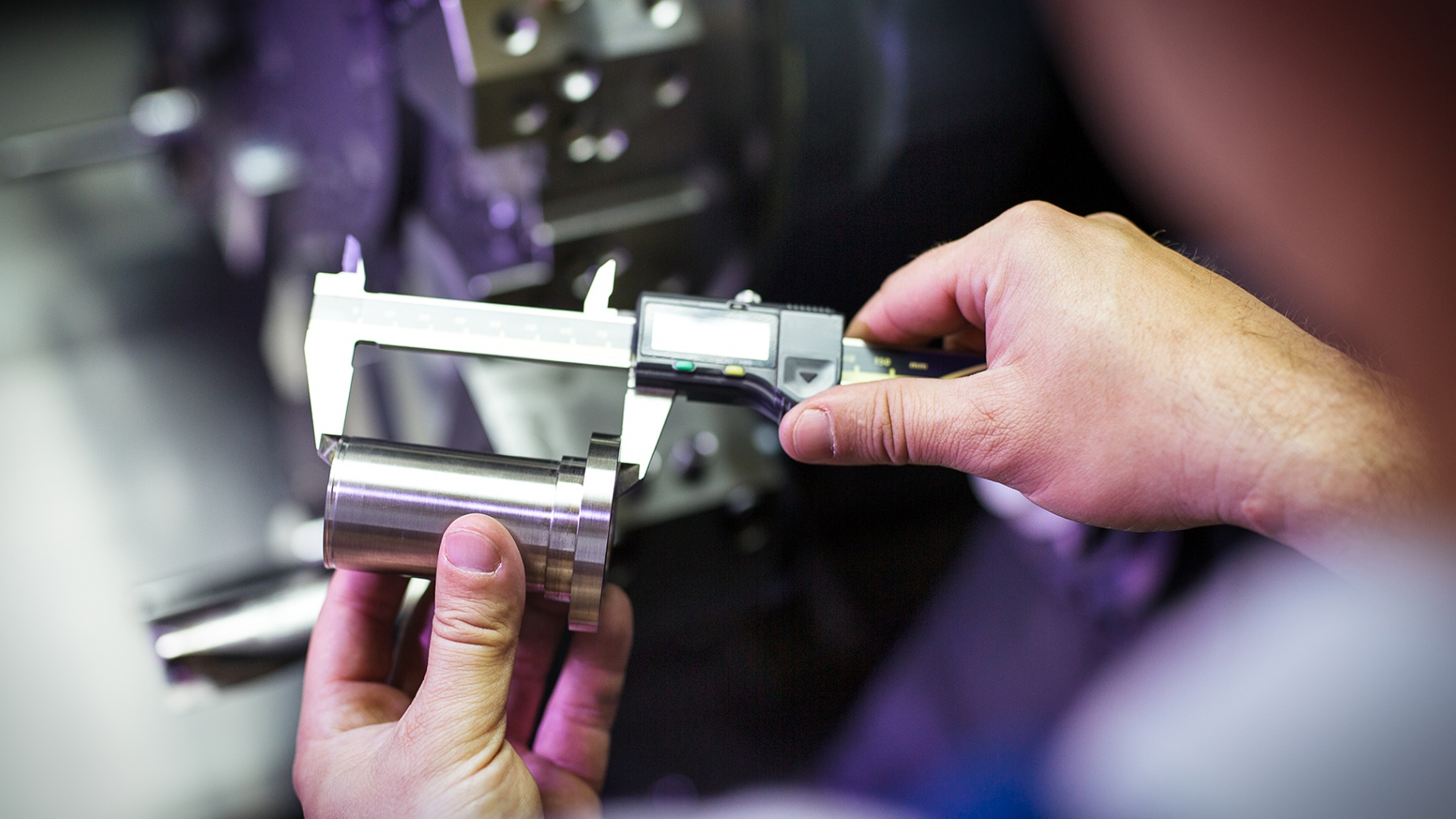

Birinci can control and test all mechanical, physical and chemical properties of the products it produces. In addition to final product approval, Birinci can perform fatigue, durability, load and torque tests during the design phase. All modern quality tools such as online SPC, visual inspection charts, 8D and Poka-Yoke are applied to the company production system.

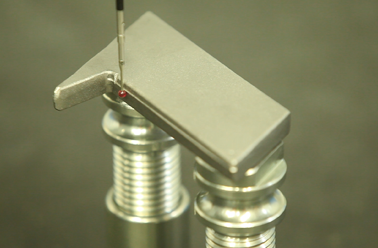

Ultrasonic test devices are used for magnetic particle inspection and crack inspections and 100% control activities according to EN10228, ISO 16232, ISO 4407 etc. with automated table scanning microscope. Residual contamination determination is possible according to standards.

Welding process qualification is done with tools such as WPS/PQR. Calibration capability is available as an internal laboratory.

Birinci focuses on increasing efficiency and customer satisfaction with Six sigma, Kaizen, 5S and Lean Manufacturing approaches.